Facilities

Electronic parts:

- SMT - Surface Mount Technology

SMT is a key process for electronic parts which the components are mounted or placed directly onto the surface of PCBs. It is a streamline production including solder paste printing, gluing, mounting, reflow, and AOI inspection for automatic separation of good / defect parts, the line is running with two inspector to assure quick reaction and quality control. - DIP - Dual In Line Package Process

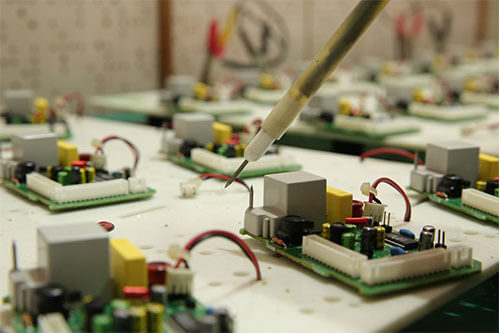

DIP process mainly used for traditional electronic component and PCBs. TbK replaced the hand soldering by Lead-free wave soldering, which avoids the component might damage due to high temperature, and lower down the possible failure rate. - ICT - In-circuit test

ICT is an electrical probe tests -- checking for shorts, opens, and the impedance of all electronic components on a loaded printed circuit board, all PCBs are 100% tested.

SMT

SMT1

Automatic coiling machine

Automatic coiling machine1

Burning test

Mechanical parts:

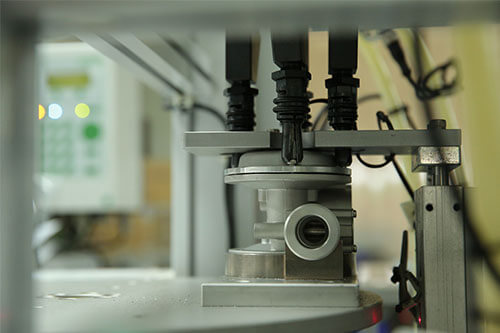

- Automatic coiling machines

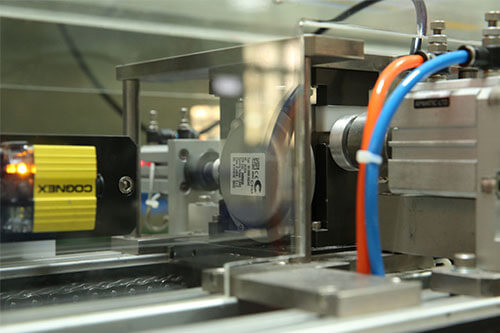

The quality of coil has great influence to the durability of gas valve. Therefore we introduced the coiling process in house to reduce the potential failures which might be caused during transportation. - Automatic function test

Gas valve is the critical safety components for gas appliance, all the tightness (high / low pressure, flow / backflow) and electronic function (opening / close voltage) must be 100% tested.With the automatic function tester, all the test could be performed automatically and the values could be records. - Screwing machine

The automatic screwing machine has advantage with fixed torque, it is equipped with detection device to select bad parts with stripped or bad thread.

Automatic assembling machine

Automatic functional tester

Automatic functional tester2

Automatic coiling machine2

Leakage tester

Leakage tester2

Leakage tester3

Screwing machine

Screwing machine2